Oil sludge, a byproduct of the petroleum industry, has long been an environmental concern due to its potential for contamination. However, in recent years, thermal desorption has emerged as a triumphant solution in the realm of oil sludge remediation. This innovative technology not only addresses the challenges posed by oil sludge but also brings forth a myriad of positive outcomes for the environment, ecosystems, and sustainable resource management. In this comprehensive exploration, we delve into the triumphs of thermal desorption unit, shedding light on its remarkable benefits in oil sludge remediation.

I. Understanding Oil Sludge: A Environmental Challenge

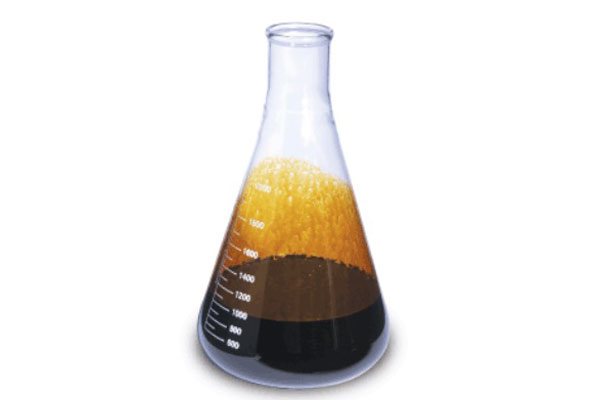

Before delving into the triumphs of thermal desorption, it’s crucial to understand the environmental challenges posed by oil sludge. Oil sludge, often referred to as tank bottoms, results from the accumulation of oil, water, and solid particles during the petroleum refining process. This mixture contains hazardous compounds, heavy metals, and hydrocarbons, making it a potent threat to soil, water, and air quality. Traditional methods of disposal, such as landfills or incineration, are not only environmentally detrimental but also fail to address the root causes of contamination.

II. The Birth of Thermal Desorption: A Game-Changing Technology

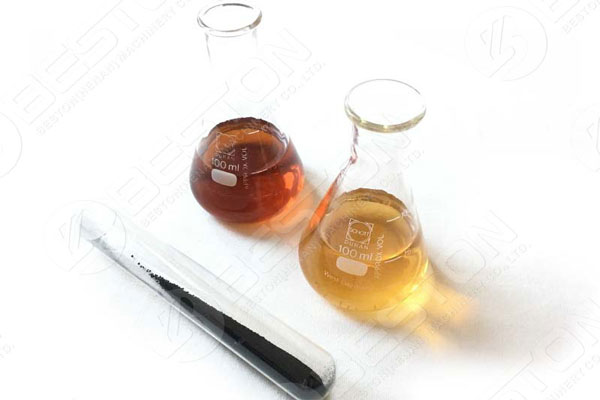

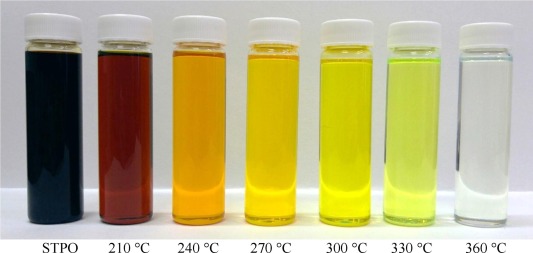

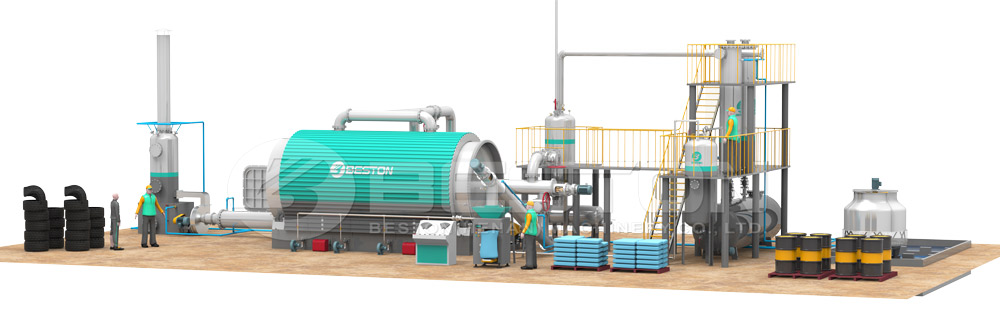

Thermal desorption, as a remediation technique, involves the use of heat to separate and recover valuable hydrocarbons from the oil sludge. This process not only minimizes waste but also transforms the sludge into reusable resources. The triumph of oil sludge pyrolysis plant for sale lies in its ability to tackle the environmental challenges posed by oil sludge through a sustainable and efficient approach.

III. Positive Outcomes in Soil Remediation:

One of the primary triumphs of thermal desorption is its effectiveness in soil remediation. The heat applied during the process not only facilitates the separation of oil, water, and solids but also helps in breaking down contaminants. As a result, the treated soil experiences a significant reduction in pollutants, leading to the restoration of soil fertility and preventing long-term environmental degradation. This outcome is particularly noteworthy in areas where traditional remediation methods have fallen short.

IV. Water Quality Improvement:

Oil sludge contamination often extends to water bodies, posing a threat to aquatic ecosystems and human health. Thermal desorption triumphs in water quality improvement by ensuring the removal of harmful substances from the sludge. The treated water is not only cleaner but also lessens the impact on aquatic life. This positive outcome contributes to the overall health and sustainability of ecosystems, marking a significant advancement in water resource management.

V. Air Quality Enhancement:

The volatile nature of hydrocarbons in oil sludge makes air quality a critical concern. Traditional disposal methods like incineration release harmful emissions into the atmosphere, exacerbating pollution. Thermal desorption, however, minimizes these environmental risks. By focusing on the separation and recovery of hydrocarbons through controlled heating, the process significantly reduces air emissions, ensuring a cleaner and healthier atmosphere.

VI. Resource Recovery and Economic Benefits:

Thermal desorption not only triumphs in environmental remediation but also contributes to resource recovery. The recovered hydrocarbons from the oil sludge can be reused in the petroleum industry, minimizing the dependency on virgin resources. This not only conserves valuable raw materials but also translates into economic benefits for industries adopting thermal desorption technologies. The triumph lies in turning a once-discarded waste stream into a valuable resource. The waste tyre pyrolysis plant manufacturer may give you some ideas.

VII. Energy Efficiency and Sustainable Practices:

The energy efficiency of thermal desorption is a key factor in its triumph. By harnessing heat as a primary tool for separation, the process minimizes energy consumption compared to traditional methods. The sustainability of thermal desorption further shines through its ability to align with the principles of circular economy and waste reduction. As industries increasingly prioritize sustainable practices, thermal desorption stands out as a triumph in achieving both environmental and economic sustainability.

VIII. Community and Stakeholder Engagement:

The positive outcomes of thermal desorption extend beyond environmental and economic realms to community and stakeholder engagement. Adopting this technology demonstrates a commitment to responsible environmental stewardship, earning the trust and support of local communities. Stakeholders, including regulatory bodies, are likely to view thermal desorption favorably due to its proven efficacy in addressing oil sludge challenges responsibly and sustainably.

IX. Case Studies: Real-World Triumphs of Thermal Desorption:

To further emphasize the triumphs of thermal desorption, examining real-world case studies provides invaluable insights. Highlighting successful applications in diverse settings, from industrial sites to oil refineries, showcases the adaptability and efficacy of thermal desorption in various contexts. These case studies serve as compelling evidence of how thermal desorption has triumphed over traditional methods, delivering positive outcomes in oil sludge remediation.

X. Future Prospects and Continuous Improvement:

As thermal desorption continues to triumph in oil sludge remediation, the future holds promise for further advancements. Ongoing research and development aim to enhance the efficiency and applicability of thermal desorption technologies. Continuous improvement in process optimization, equipment design, and integration with other remediation techniques will contribute to even more significant triumphs in addressing environmental challenges associated with oil sludge.

Conclusion:

In conclusion, the triumphs of thermal desorption in oil sludge remediation are undeniably transformative. From soil remediation and water quality improvement to resource recovery and sustainable practices, thermal desorption emerges as a game-changer in environmental stewardship. The positive outcomes extend beyond the immediate remediation process, influencing community perceptions, stakeholder engagement, and industry practices. As we embrace this innovative technology, the triumphs of thermal desorption pave the way for a cleaner, healthier, and more sustainable future.