If you’re in the market for a manual egg tray making machine, it’s important to understand the different parts that make it up. In this article, we will take a look at each of the parts and explain their function. We’ll also give you some tips on what to look for when purchasing a manual egg tray making machine. So, whether you’re just starting out in the egg tray business or you’re looking to upgrade your current machine, read on for all the information you need!

Different parts of an egg tray making machine

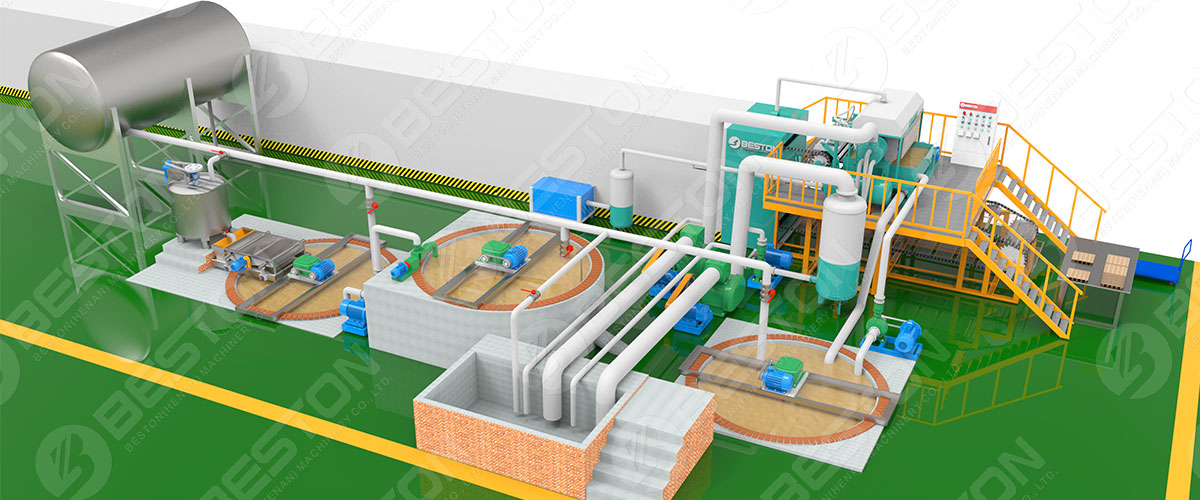

An egg tray making machine is an integral part of the egg packaging process. It takes raw egg trays, usually made from recycled paper or cardboard, and attaches them to one another using a molding system. The machine then applies pressure to the trays, shaping them into specific combinations and sizes.

As the name suggests, industrial packaging machinery is usually composed of multiple parts working together to achieve their goal – such as forming molds or compressing trays with varied amount of force. Additionally, egg tray making machines have their own dedicated controls that allow for adjusting levels of pressure and forming size according to needs. With the popularity of sustainable packaging increasing in the world-wide market, these machines are becoming more common than ever before.

Functions of each part

It’s important to understand the different parts and their functions when looking for an egg tray making machine. The main components are:

1. Molds – These hold the trays in place while they’re being molded into shape.

2. Vacuum Pressure Pump – This is what creates the pressure needed to form the trays.

3. Forming Chambers – This is where the molds are held, and it’s where the vacuum pressure from the pump is applied.

4. Motor – This is what powers the entire egg tray making machine, and it’s usually electric or gas-powered.

5. Heating System – This is what heats the trays before they are molded, ensuring that they can be easily shaped into their desired shape.

6. Cooling System – This is what cools the trays down once they have been molded, allowing for them to keep their shape.

So, when shopping for an egg tray making machine, be sure to check all of these components and ensure that they’re in good working condition. Additionally, you’ll want to look for a machine that has adjustable pressure settings and can produce different sizes and shapes of trays. With all these features, you’ll be sure to find the perfect egg tray making machine for your needs: https://pulpmouldingmachines.com/egg-tray-manufacturing-machine/.

Tips for purchasing an egg tray making machine

There are a few things to keep in mind when purchasing an egg tray making machine. First, you should make sure that the machine is made from quality materials and is up to the task of producing quick and efficient results. Additionally, you should make sure that the egg box making machine has adjustable pressure settings so you can easily adjust the pressure levels to suit your needs. It also helps to find a machine that is easy to operate and comes with clear instructions so that you don’t have any problems setting it up and running it.

By keeping these tips in mind, you’ll be sure to find the perfect egg tray making machine for your business.