In the quest for sustainable solutions to our environmental challenges, the circular economy has emerged as a guiding principle. At its core lies the idea of reducing waste and maximizing resource efficiency through innovative approaches. One such innovation making waves is wood pyrolysis—a process that transforms wood waste into valuable products while exemplifying the principles of the circular economy. This article explores how wood pyrolysis is redefining recycling, offering a sustainable alternative to traditional waste management practices and fostering a more circular approach to resource utilization.

The Challenge of Wood Waste

Wood is a ubiquitous material used in construction, furniture manufacturing, and various industries worldwide. However, the production and consumption of wood products generate significant amounts of waste, including offcuts, sawdust, and discarded timber. Disposing of this wood waste poses environmental challenges, from occupying landfill space to emitting greenhouse gases during decomposition. Traditional disposal methods, such as incineration or landfilling, not only contribute to environmental pollution but also squander the potential value inherent in wood waste. Get to know the function of wood charcoal making machine.

Enter Wood Pyrolysis

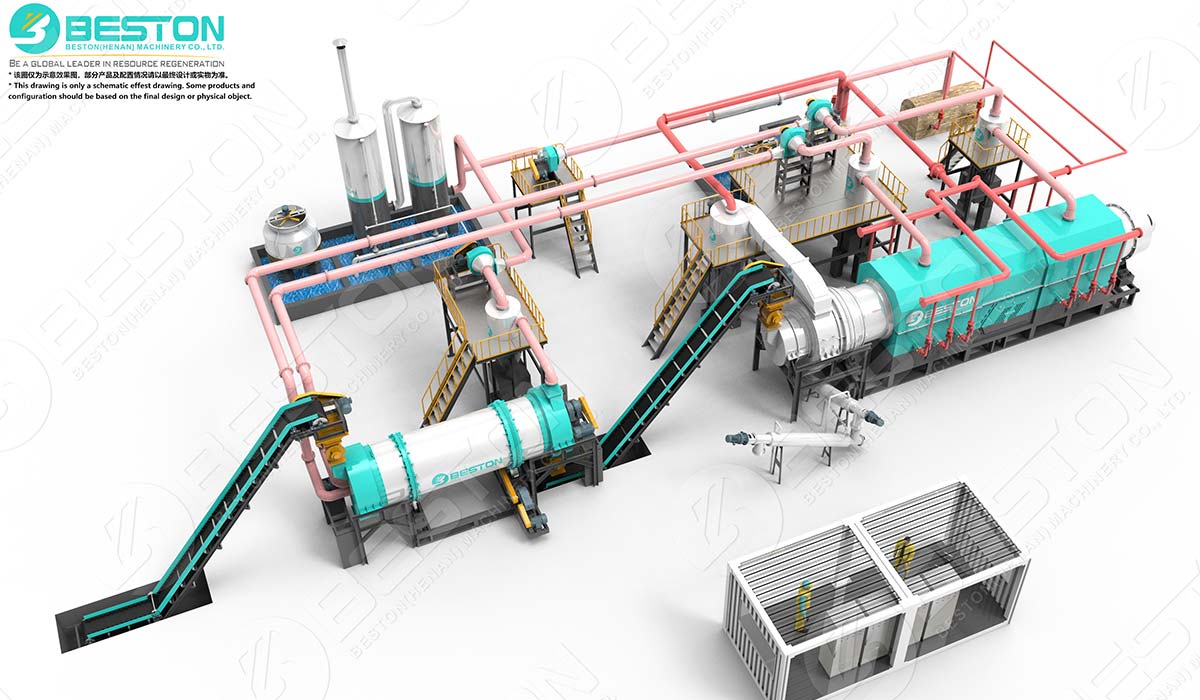

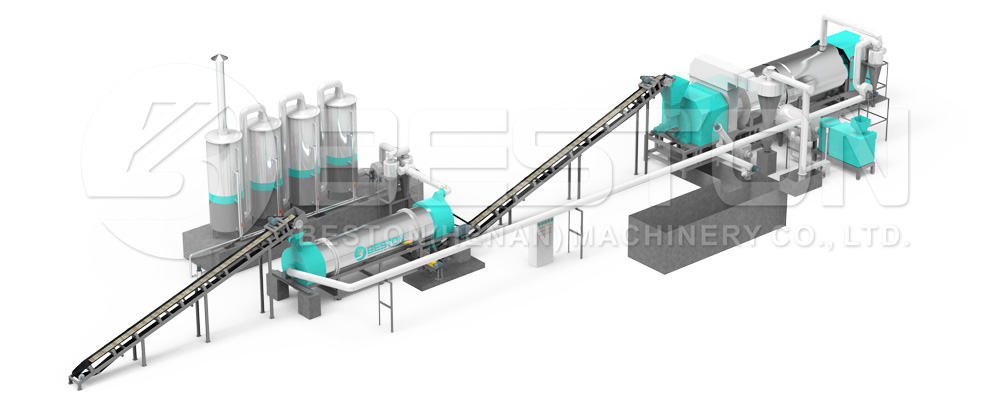

Wood pyrolysis offers a sustainable solution to the challenge of wood waste by converting it into valuable resources through a thermal decomposition process conducted in the absence of oxygen. The process typically involves heating wood biomass at elevated temperatures (around 400-600°C) in a controlled environment, leading to the breakdown of complex organic molecules into simpler compounds. This thermochemical conversion yields three primary products:

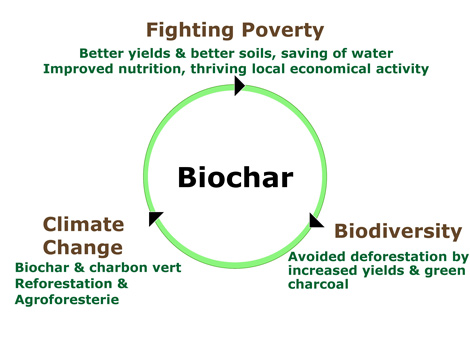

- Biochar: A carbon-rich solid residue resembling charcoal, biochar has diverse applications, including soil amendment, carbon sequestration, and filtration.

- Bio-oil: Also known as pyrolysis oil or wood tar, bio-oil is a liquid mixture of organic compounds derived from the thermal decomposition of wood biomass. It can be further processed into biofuels, chemicals, or used directly as a fuel source.

- Syngas: A mixture of hydrogen, carbon monoxide, methane, and other gases, syngas can be utilized as a clean energy source for heat and power generation or converted into fuels and chemicals through additional processing. See the coconut shell charcoal making machine here.

Environmental and Economic Benefits

Wood pyrolysis offers several environmental and economic benefits that align with the principles of the circular economy:

- Waste Reduction: By converting wood waste into valuable products, wood pyrolysis mitigates the need for landfilling or incineration, thereby reducing the environmental footprint associated with wood disposal.

- Resource Recovery: The production of biochar, bio-oil, and syngas from wood waste represents a form of resource recovery, harnessing the inherent value of biomass and promoting a closed-loop approach to resource utilization.

- Carbon Sequestration: Biochar produced through wood pyrolysis can serve as a stable form of carbon storage when applied to soil, contributing to climate change mitigation efforts by sequestering carbon and enhancing soil fertility.

- Renewable Energy: The syngas and bio-oil generated from wood pyrolysis offer renewable alternatives to fossil fuels, reducing dependence on non-renewable resources and lowering greenhouse gas emissions.

- Economic Opportunities: Wood pyrolysis presents economic opportunities through the production and sale of biochar, bio-oil, and syngas, as well as potential revenue streams from carbon offset credits and soil carbon sequestration initiatives. Check the benefits of charcoal making machine here.

Challenges and Considerations

While wood pyrolysis holds great promise, certain challenges and considerations must be addressed to realize its full potential:

- Feedstock Availability: The availability and quality of wood biomass for pyrolysis may vary regionally, necessitating efficient collection and processing systems to ensure a consistent supply of feedstock.

- Technology Optimization: Continuous research and development efforts are needed to optimize pyrolysis processes, improve product yields, and enhance the efficiency of energy conversion technologies.

- Market Demand: The market demand for pyrolysis products, such as biochar and bio-oil, may fluctuate depending on factors such as regulatory incentives, consumer preferences, and competing technologies, influencing the economic viability of wood pyrolysis ventures.

- Environmental Impact: While wood pyrolysis offers environmental benefits, the process itself may generate emissions and require energy inputs, highlighting the importance of adopting best practices to minimize environmental impact and ensure sustainability.

Conclusion

Wood pyrolysis exemplifies the circular economy in action, transforming wood waste into valuable resources while minimizing environmental impact and fostering economic prosperity. By harnessing the potential of biomass through thermochemical conversion, wood pyrolysis offers a sustainable alternative to traditional waste management practices and contributes to the transition towards a more circular and resource-efficient economy. As advancements in technology and regulatory frameworks continue to evolve, wood pyrolysis holds promise for revolutionizing recycling and promoting a greener, more sustainable future for generations to come. Visit the Beston Group here.