In the ever-evolving landscape of waste management and sustainable solutions, pyrolysis emerges as a groundbreaking technology that reaches far beyond recycling. It’s a transformative process with the potential to reshape how we view and utilize our waste, while offering a myriad of applications, from fuel production to environmental remediation.

Pyrolysis, in its essence, is a thermal decomposition technique that involves heating organic materials in an oxygen-deprived environment. This controlled degradation process of pyrolysis plant results in the production of a valuable substance known as pyrolysis oil, among other byproducts.

Turning Waste into Energy: The Fuel Aspect

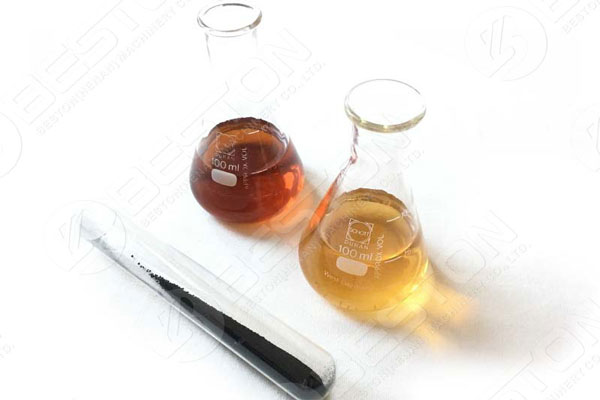

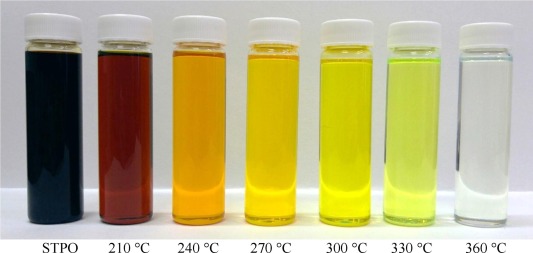

At the heart of pyrolysis lies its remarkable ability to convert various forms of waste, such as plastics, rubber, and biomass, into a valuable resource: pyrolysis oil. This dark, viscous liquid, often referred to as “liquid gold,” is a versatile fuel that has the potential to reduce our reliance on fossil fuels.

Pyrolysis oil can be used as a substitute for diesel or even be further refined into transportation fuels, making it a promising player in the renewable energy sector. The process not only addresses the issue of waste disposal but also contributes to the reduction of greenhouse gas emissions, thus championing environmental sustainability.

Circular Economy Champion: Resource Recovery

Unlike traditional recycling methods, batch/continuous pyrolysis palnt allows for the recovery of a broader range of materials, including those that are difficult to recycle using conventional means. Plastics contaminated with food residues or mixed materials can be effectively processed through pyrolysis, giving them a new lease on life.

The concept of a circular economy, where resources are reused and recycled as efficiently as possible, aligns perfectly with pyrolysis technology. It embodies the idea of waste not being the end of the line but rather a stepping stone towards the creation of new resources.

Environmental Cleanup: Remediating Contaminated Soil

Pyrolysis isn’t just limited to waste-to-fuel applications. It is proving to be an invaluable tool in environmental remediation. Contaminated soil, polluted with hazardous substances, can be treated with pyrolysis to break down and remove the contaminants.

The high-temperature process causes the contaminants to decompose, leaving behind clean soil that can be reintegrated into the environment. This eco-friendly approach mitigates the harmful effects of soil pollution, a critical step in preserving ecosystems and human health.

Beyond Energy and Environment: The Spectrum of Applications

The versatility of rubber/oil sludge/tyre/plastic pyrolysis plant goes beyond waste management and pyrolysis oil production. It extends to various industries and applications:

- Agriculture: Pyrolysis-derived biochar, a charcoal-like material, enhances soil quality, increases water retention, and sequesters carbon, promoting sustainable agriculture.

- Chemical Industry: The byproducts of pyrolysis can serve as feedstock for the production of chemicals, contributing to the reduction of virgin resource consumption.

- Carbon Black Production: The process yields carbon black, an essential component in the rubber and automotive industries.

- Steel Industry: Pyrolysis-derived syngas can be used as a reducing agent in the steel manufacturing process, reducing carbon emissions.

Conclusion: A Paradigm Shift in Waste Management

The versatility of pyrolysis technology transcends the boundaries of recycling, offering a holistic approach to waste management and resource recovery. From the production of valuable pyrolysis oil to the remediation of contaminated environments, plastic/tyre to oil plant through pyrolysis stands at the forefront of sustainable and eco-friendly solutions.

In a world where waste is a growing concern, pyrolysis offers a ray of hope, showing us that waste can be transformed into a resource, and that a circular economy is not just an ideal but an achievable reality. As pyrolysis technology continues to evolve, we are on the cusp of a paradigm shift in waste management, one that holds the promise of a cleaner, more sustainable future.